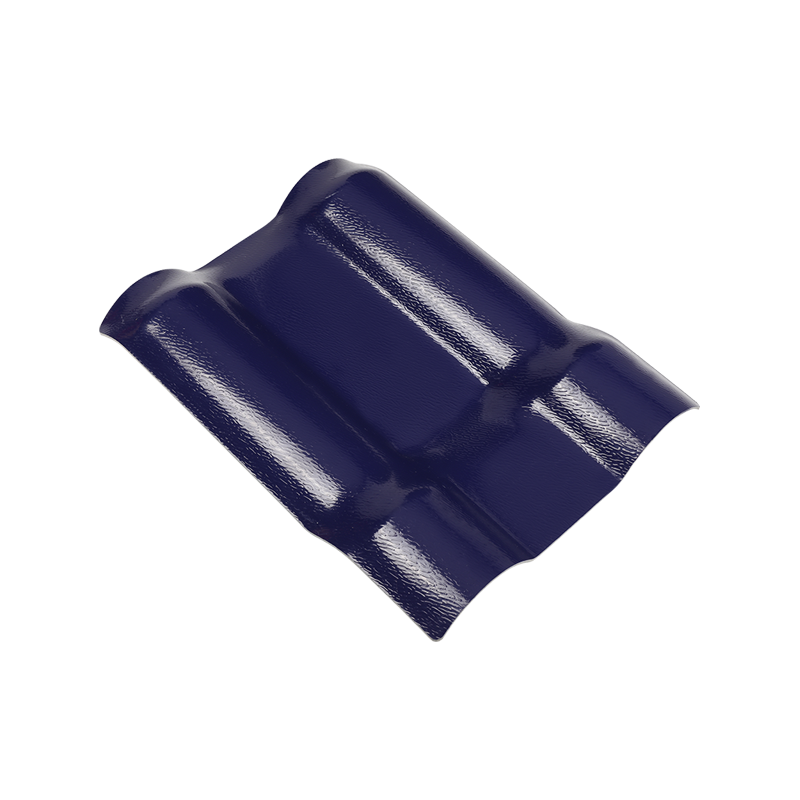

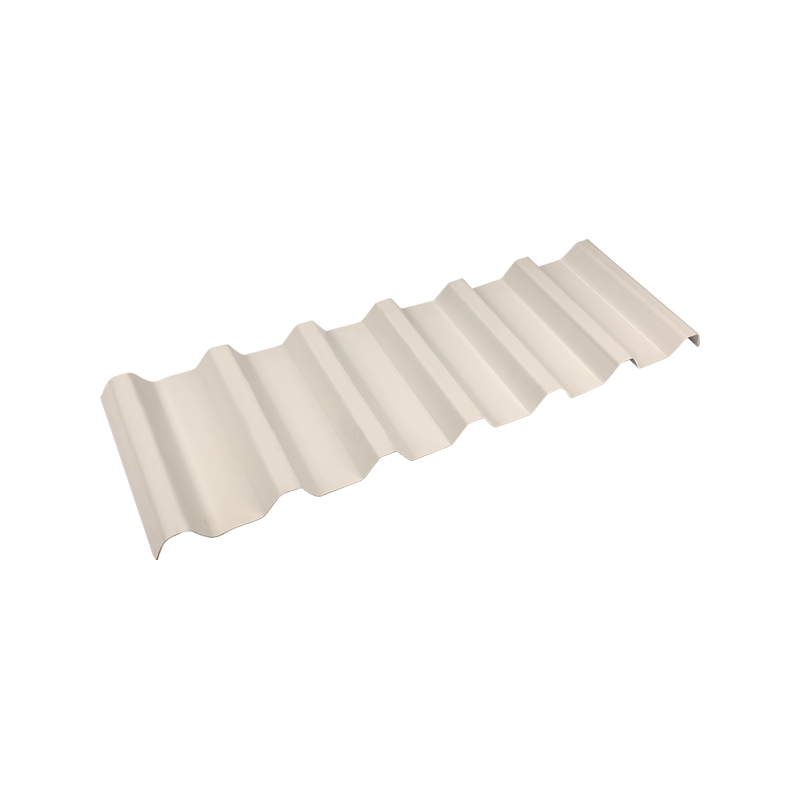

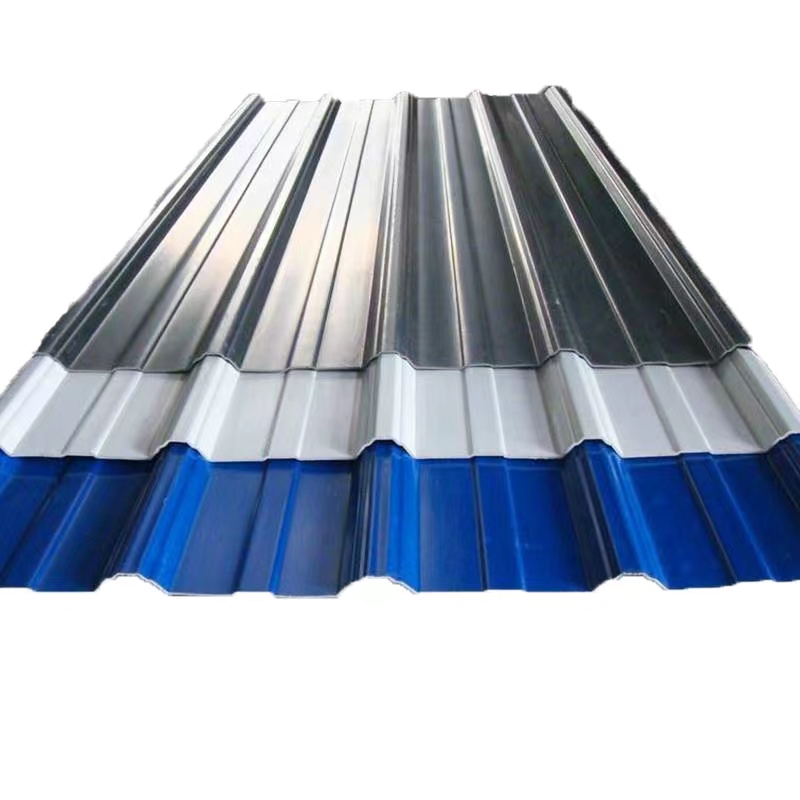

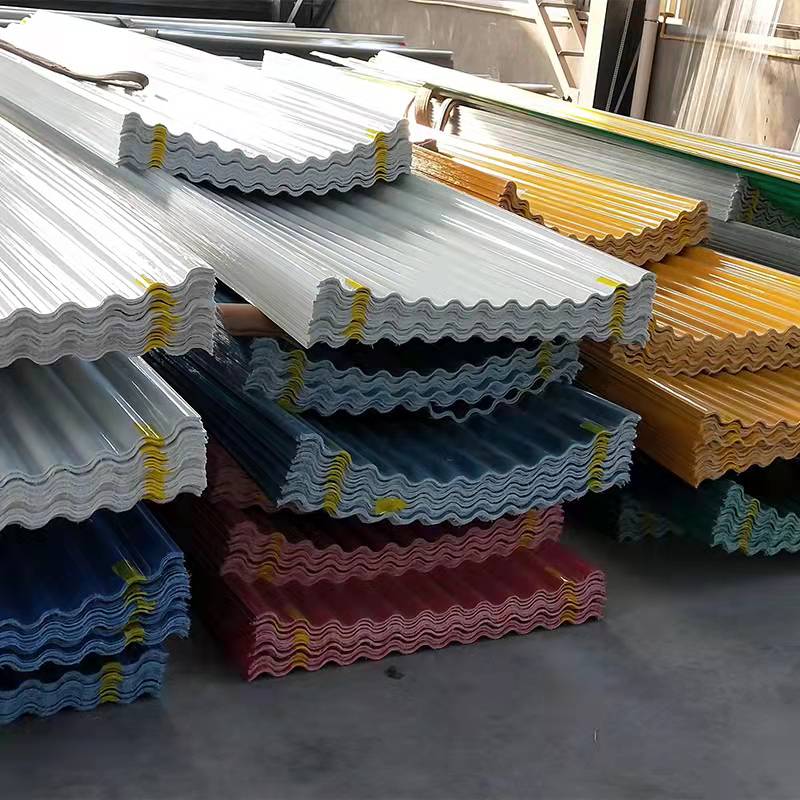

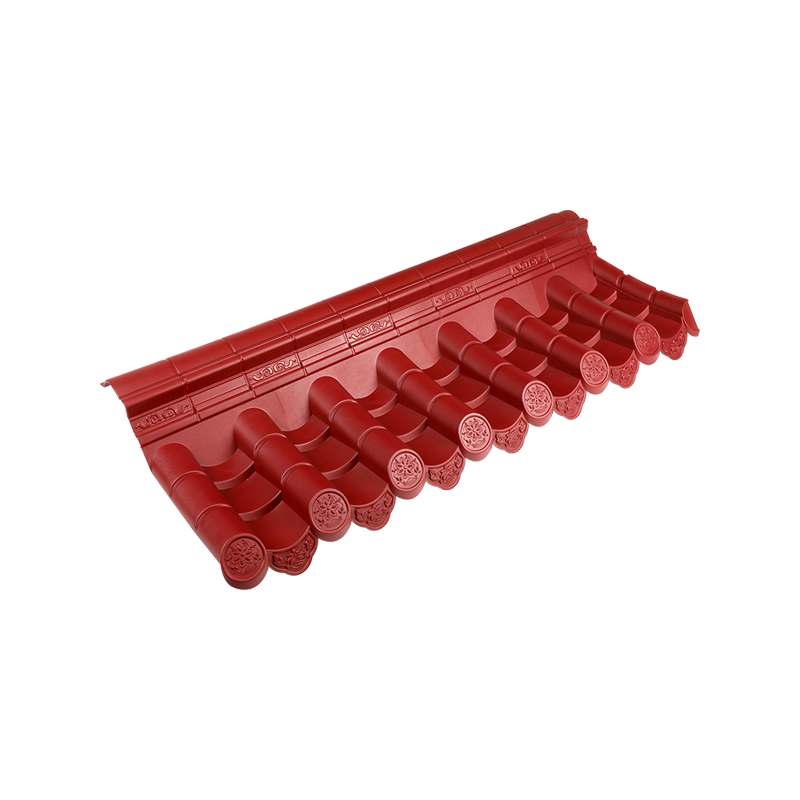

UV-PVC tile, that is, polyvinyl chloride (PVC) tile with ultraviolet light curing layer (UV layer), its anti-aging performance benefits from many factors, including the characteristics of PVC material itself, the protective effect of UV layer and reasonable production and use conditions.

1. The basis of anti-aging of PVC material

As a polymer material, PVC has polar chlorine atoms, which provides it with good chemical stability, making PVC itself have good weather resistance and chemical corrosion resistance. However, the anti-aging performance of PVC is also affected by its molecular weight, branched structure, crystallinity and other factors. In order to further improve the anti-aging performance of PVC, additives such as heat stabilizers, ultraviolet absorbers, light stabilizers, antioxidants, etc. are usually added to resist thermal degradation during processing, ultraviolet degradation caused by long-term exposure to sunlight, and performance degradation caused by oxidation reactions.

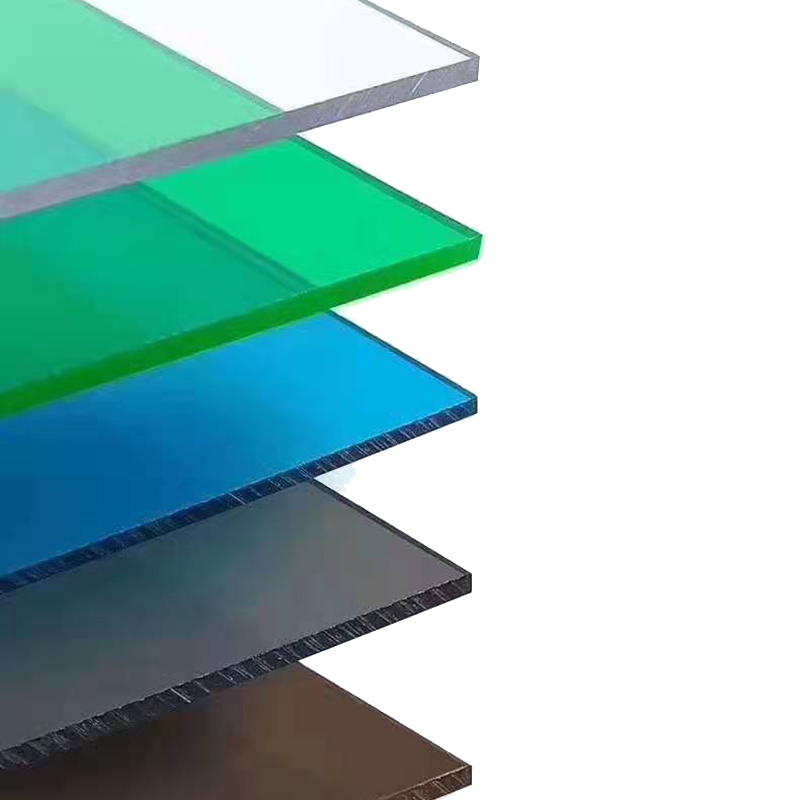

2. The protective effect of UV layer

The full name of UV layer is ultraviolet curing layer, which is a protective film formed on the surface of PVC tiles through advanced UV treatment technology. This film is mainly composed of environmentally friendly and non-toxic organic polymer materials such as modified polyurethane. It has excellent adhesion, dimensional stability, mildew resistance, and enhanced wear resistance and impact resistance. The presence of the UV layer provides a "protective coat" for PVC tiles, greatly improving its anti-aging performance: Anti-ultraviolet aging: The UV layer can effectively absorb and reflect ultraviolet rays, greatly slowing down the color change and physical property degradation caused by ultraviolet radiation on the surface of PVC tiles, and keeping the color of UV-PVC tiles lasting and bright. Enhanced wear resistance: By reinforcing the surface of UV-PVC Tile, the UV layer greatly enhances the wear resistance of UV-PVC tiles, reduces surface damage caused by friction and impact, and thus extends the service life of UV-PVC tiles. Anti-pollution and easy to clean: The UV layer also has certain anti-pollution properties, which can effectively resist various stains in daily life, keep the tiles clean and hygienic, and easy to clean and maintain. 3. Reasonable production and use conditions In addition to the protective effect of PVC materials and UV layers, reasonable production and use conditions are also important factors to ensure the anti-aging performance of UV-PVC Tile. During the production process, the quality of raw materials, the type and amount of additives, and the production process parameters should be strictly controlled to ensure the quality of the finished UV-PVC tile. During use, unfavorable factors such as long-term high temperature exposure, chemical corrosion, and mechanical stress should be avoided to reduce the aging speed of UV-PVC Tile.

The anti-aging performance of UV-PVC Tile benefits from the excellent performance of the PVC material itself, the strong protective effect of the UV layer, and reasonable production and use conditions. These factors work together to keep the UV-PVC tile stable in physical properties and beautiful appearance during long-term use, thereby extending its service life. When selecting and using UV-PVC tiles, their anti-aging properties should be fully considered, and corresponding measures should be taken to maintain their good use status.

Email:

Email: Phone:

Phone: Adress:

Adress: