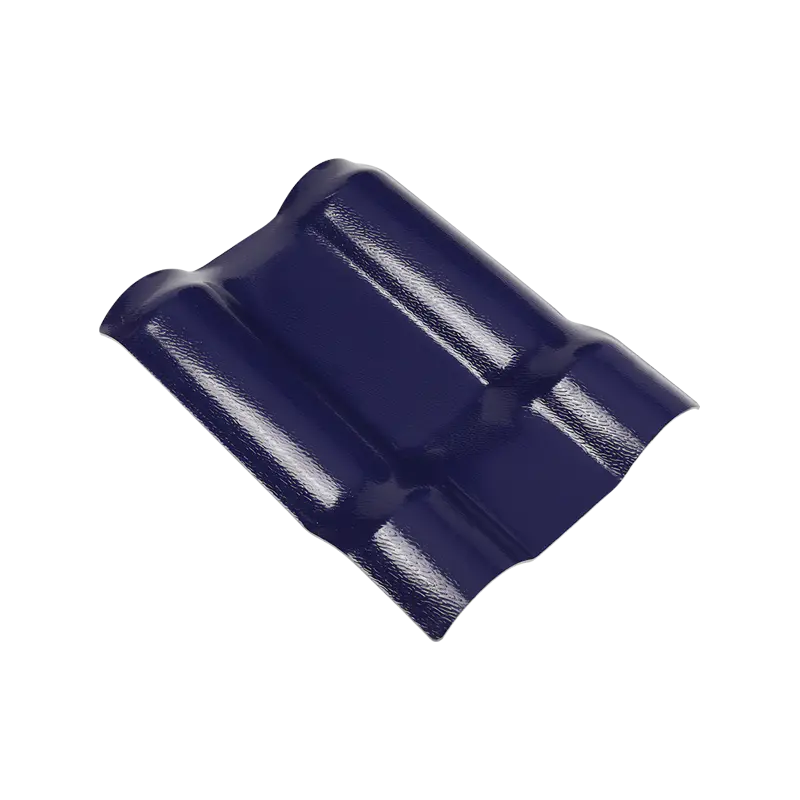

1. Weathering test

A key feature of Chinese ASA Resin Tile Manufacturers is its excellent weathering resistance, which means that it can maintain stable performance for a long time under various climate conditions. Weathering tests simulate the performance of resin tiles in different weather environments to ensure that they will not fade, age or crack after long-term use. Specific test items include:

Ultraviolet (UV) radiation test: UV radiation is one of the main factors causing aging, embrittlement and fading of resin materials. Manufacturers usually expose ASA resin tiles to strong UV light through artificial accelerated aging tests to simulate the performance changes of products under long-term sunlight. The test is usually carried out under ambient temperature and humidity control to determine whether the resin tile surface fades, cracks or surface damage occurs.

High temperature aging test: The stability of resin tiles in high temperature environments is another key indicator. By exposing the resin tiles to high temperature environments (such as 60℃ to 80℃), long-term exposure to hot climates is simulated. The test results help determine the performance of resin tiles in terms of thermal deformation, strength loss and surface aging.

Wet and hot cycle test: The wet and hot cycle test simulates the use of resin tiles in tropical or humid climates by repeatedly exposing them to high temperature and high humidity. This test can examine whether the resin tiles are prone to water swelling or material deformation in a humid and high temperature environment.

2. Ultraviolet (UV) resistance test

In the production process of Chinese ASA Resin Tile Manufacturers, UV resistance is considered a very important performance indicator. Although ASA resin itself has strong UV resistance, manufacturers still conduct intensive tests to verify its durability in harsh environments. UV resistance testing usually uses the following methods:

Accelerated UV exposure test (QUV test): This test uses UV-A or UV-B lamps to simulate the long-term effects of natural UV on the surface of resin tiles. The test usually lasts for hundreds to thousands of hours to evaluate the discoloration, surface cracks and changes in the mechanical properties of the resin tiles under UV irradiation.

Spectral analysis: By analyzing the reaction of resin tiles under UV radiation of different wavelengths, manufacturers can optimize the UV resistance of ASA resin to ensure that it is not easy to fade and become brittle in long-term use.

3. Wind pressure and impact resistance test

In actual applications, resin tiles often face the challenges of strong winds, heavy rains and other external forces, especially in some areas with strong winds, where wind pressure resistance is crucial. In order to verify the wind pressure resistance of ASA resin tiles, manufacturers usually conduct the following tests:

Wind pressure test: By simulating wind pressure of different intensities in a wind tunnel, manufacturers can evaluate whether resin tiles can be firmly fixed on the roof in a strong wind environment. This test is particularly important because excessive wind pressure can cause tiles to fall off or shift, affecting the safety of the house.

Impact resistance test: The impact resistance of resin tiles is an important factor in evaluating their durability. By using steel balls or other hard objects to hit the resin tiles, manufacturers can evaluate whether the tiles will break or deform when impacted by external forces. This test ensures the safety of ASA resin tiles in storms, hail or other emergencies.

4. Corrosion resistance test

Although ASA resin tiles have good chemical corrosion resistance, they still need to undergo long-term corrosion resistance tests, especially in highly corrosive environments such as seaside or industrial areas. Corrosion resistance tests are carried out in the following ways:

Salt spray corrosion test: Simulate salt spray environments such as the seaside, and expose resin tiles to salt spray to check whether they will cause surface corrosion or physical damage due to salt accumulation. This type of test is especially important for resin tiles used in coastal areas.

Acid and alkali corrosion test: Simulate the erosion environment of acid rain or chemical gases to evaluate whether resin tiles will undergo chemical reactions, resulting in material degradation or performance degradation.

5. Frost resistance test

For the use environment in cold areas, ASA resin tiles need to have certain frost resistance to avoid embrittlement and cracking of the material due to sudden temperature drops. Frost resistance tests usually include:

Low temperature impact test: Expose ASA resin tiles to low temperature environments to observe whether they can maintain good mechanical strength and withstand external force impacts at low temperatures. This test can verify whether the resin tiles are suitable for winter cold and snow pressure environments.

Freeze-thaw cycle test: simulates the environment of alternating ice and snow, and tests whether the resin tile will expand, shrink or crack during the freezing and thawing process through repeated freezing and thawing. This test can verify the durability of the resin tile in cold areas.

6. Long-term exposure and actual use monitoring

In addition to accelerated aging tests in the laboratory, many manufacturers will also conduct long-term actual use monitoring in different regions and environments to obtain more realistic performance data. This includes:

Long-term use case study: ASA resin tiles are installed on actual buildings for long-term monitoring for several years or even ten years, and data including appearance, structural strength, anti-aging, pollution resistance, etc. are collected to ensure the performance of the product in a real environment.

Customer feedback and market research: Manufacturers will also regularly collect feedback from users, pay attention to the long-term performance of products in different regions, and adjust and optimize product design and manufacturing processes in a timely manner.

Email:

Email: Phone:

Phone: Adress:

Adress: