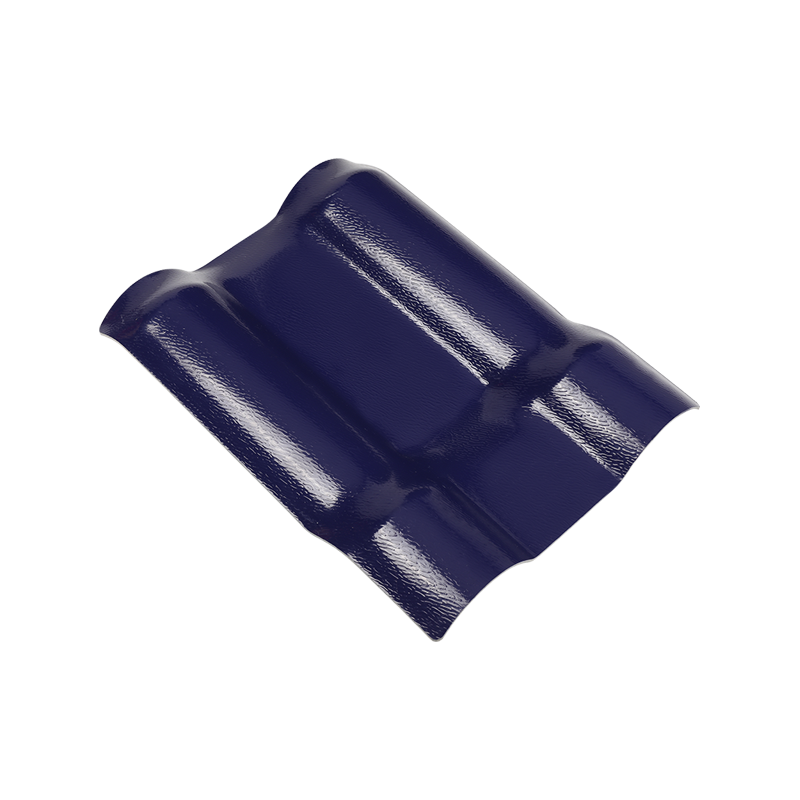

1. Optimizing the ratio of resin and ceramic materials

The compression resistance of resin tiles is first affected by the ratio of resin and ceramic components. As a binder and reinforcing agent, resin usually occupies a large proportion and determines the hardness and strength of tiles. In order to improve the compression resistance, the selection and dosage of resin need to be precisely controlled.

Resin selection: The type and performance of resin have a great influence on the compression resistance. Generally, epoxy resin, phenolic resin or unsaturated polyester resin have good hardness and compression resistance. Epoxy resin is widely used in resin tiles that require higher compression resistance due to its high curing strength and hardness. Choosing the right resin material can enhance the compression resistance of tiles.

Ceramic powder ratio: Increasing the proportion of ceramic components helps to improve the hardness of resin tiles. The type, particle size and quality of ceramic powder directly affect the compression resistance of tiles. The use of high-purity and high-strength ceramic powder can effectively improve the hardness and strength of the final product and enhance the compression resistance.

Fillers and Reinforcers: Adding mineral fillers or reinforcing agents (such as glass fiber, carbon fiber, etc.) to the resin can significantly improve the compressive resistance of the tile. Glass fiber and carbon fiber can provide additional strength and toughness to prevent cracks or breakage under high pressure.

2. Control the temperature and pressure during the production process

The production process of Resin Tile has an important impact on its compressive resistance. During the resin curing process, the control of temperature and pressure directly affects the density, hardness and stability of the internal molecular structure of the tile.

Temperature control: The curing temperature plays a vital role in the strength of resin tiles. Too high or too low temperature may lead to incomplete curing of the resin, which in turn affects the compressive performance. Generally, the curing temperature of resin tiles is between 150°C and 200°C. Reasonable control of the curing temperature can ensure that the resin is fully cured, thereby improving the hardness and compressive resistance of the tile.

Pressure control: During the molding process of Resin Tile, appropriate pressure can make the resin and ceramic powder more closely combined and improve the density of the tile. High-pressure molding process can effectively reduce voids and defects, thereby improving the overall strength of tiles and enhancing their compressive resistance.

3. Improve the molding process of resin tiles

In addition to materials and process conditions, the molding method of resin tiles will also affect their compressive resistance. The molding process of resin tiles mainly includes compression molding, injection molding and calendering molding. By optimizing the molding process, the compressive resistance of tiles can be improved.

Compression molding: The compression molding process can be used to compact the resin and ceramic powder under high pressure, so that the density of the resin tile is improved, thereby improving the compressive resistance. By precisely controlling the design of the mold and the molding pressure, it can be ensured that each tile is evenly compressed, avoiding local over-compression or incomplete compaction, thereby enhancing the overall compressive resistance.

Injection molding: The injection molding process is suitable for the production of resin tiles with high precision requirements. This process injects the resin mixture into the mold to ensure the uniformity and high density of the tile, reduce voids and uneven structures, and thus improve the compressive resistance.

Calendering: The calendering process can achieve thin and strong resin tile products by rolling resin and ceramic powder at high temperature and high pressure. This process is suitable for the production of thin tiles and can significantly improve the compression resistance of tiles.

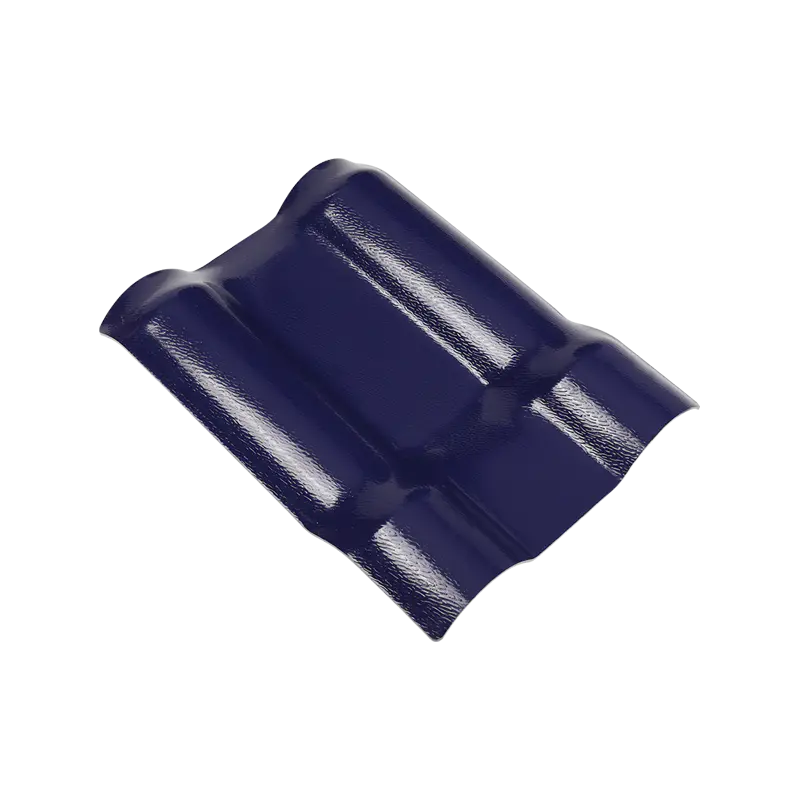

4. Increase the thickness of the product

The thickness of the resin tile has a direct impact on the compression resistance. Generally speaking, the thicker the tile, the stronger the compression resistance. By increasing the thickness of the resin tile, its overall strength and compression resistance can be improved. However, increasing the thickness may increase the weight of the material and affect the appearance and use scenarios of the tile. Therefore, when designing the thickness, it is necessary to weigh it according to the actual use needs.

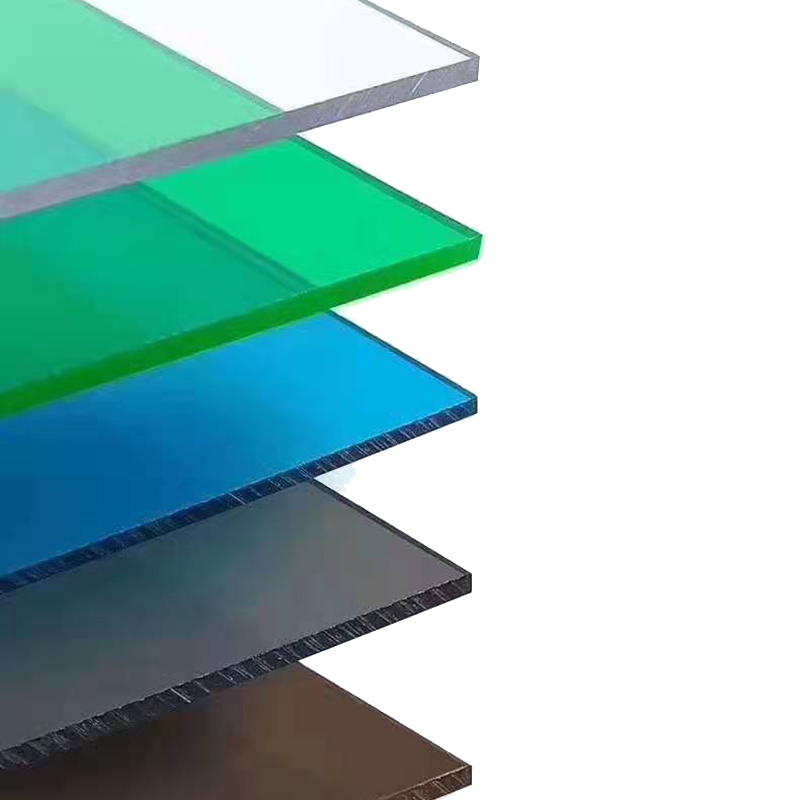

Double-layer or multi-layer design: In order to improve the compression resistance without adding too much weight, resin tiles can adopt a double-layer or multi-layer structure. The inner layer uses high-strength ceramic materials or reinforced resins, while the outer layer uses a highly decorative resin layer. Such a multi-layer design can improve the overall compression resistance while maintaining lightweight.

5. Post-processing and reinforcement

After forming, the resin tile can also be further improved through some post-processing to improve the compression resistance. Common post-strengthening methods include heat treatment, surface coating treatment, and the use of reinforcing coatings.

Heat treatment: The strength of cured resin tiles can be further improved through appropriate heat treatment. For example, high temperature treatment can make the resin molecules more closely arranged, thereby enhancing their compressive resistance.

Surface coating treatment: Applying a reinforcing coating (such as a wear-resistant layer, an anti-slip layer, etc.) on the surface of the resin tile can effectively improve the compressive resistance of the tile, improve its wear resistance, and extend its service life.

Reinforcing coating: Some special reinforcing coatings, such as high-strength ceramic coatings and nanomaterial coatings, can form a strong protective layer on the surface of the resin tile, enhance its compressive resistance and resist the invasion of external pressure.

6. Regular testing and quality control

Improving the compressive resistance of Resin Tile is not only the result of technological improvements, but also requires strict quality control to ensure the stability of each batch of products. Regular compression performance tests, including standard compression strength tests, bending strength tests, etc., can help manufacturers discover potential problems in a timely manner and make adjustments.

Email:

Email: Phone:

Phone: Adress:

Adress: