1. The Core Concept of Lean Production

Lean Production is a management model that seeks to produce products with the least waste in the shortest time. Its core concept is to improve production efficiency and quality, maximize resource utilization and reduce costs by eliminating all non-value-added activities in the production process.

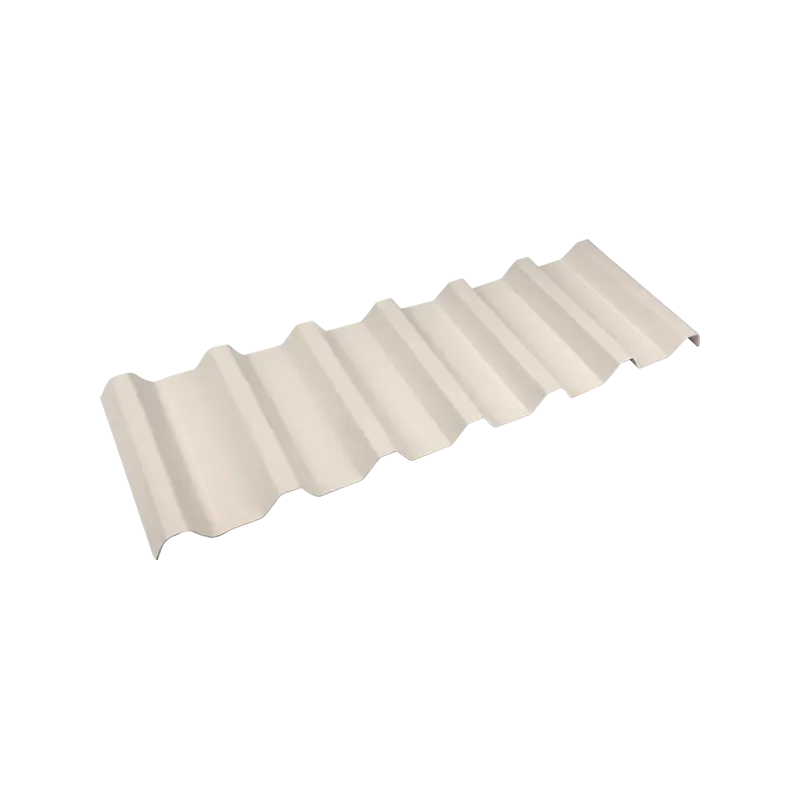

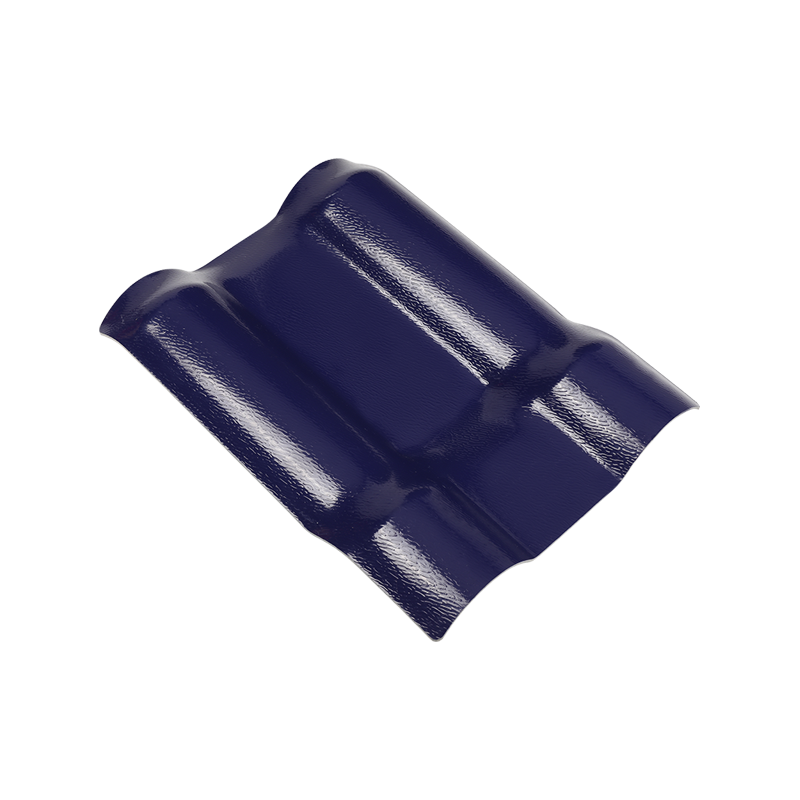

In Chinese Roofing Materials Manufacturers, the application of lean production is particularly prominent, mainly reflected in the following aspects:

Reducing waste

A core goal of lean production is to eliminate waste, which includes overproduction, waiting time, transportation, inventory, processing, movement and defective products. In the production process of roofing materials, by adopting modern equipment and technology, enterprises can optimize the production process and reduce the loss and waste of raw materials. By analyzing each link of the production line, determine which activities do not contribute to the production value, and take corresponding measures to streamline them. By adjusting the production rhythm and work flow, reducing waiting and ineffective processing time, the production of products is smoother and more efficient.

Quickly respond to market demand

The market demand for roofing materials is highly volatile, especially under the influence of cyclical fluctuations in the construction industry, traditional production methods often lead to excessive inventory backlogs or insufficient production capacity. The "pull production" method of lean production can achieve faster production adjustments by accurately calculating market demand, avoiding overproduction and inventory backlogs. Through close cooperation with customers, roofing material manufacturers can grasp changes in market demand in real time, adjust production plans, and respond quickly to market changes.

Continuous improvement

Lean production emphasizes continuous improvement, and reduces waste and non-value-added activities in the production process by continuously optimizing production processes and processes. Roofing material manufacturers regularly evaluate production processes, identify and eliminate inefficient links, and continuously improve production efficiency. Through employee participation and suggestions, improve various details in the process, such as the operating efficiency of machinery and equipment, employee operating specifications, and the rational use of materials, so as to maximize production efficiency.

2. Optimization of inventory management

In supply chain management, inventory management is a crucial link, which directly affects production efficiency, capital turnover, and corporate profitability. Roofing material manufacturers have not only reduced inventory costs but also improved product delivery timeliness through refined inventory management. The main measures to optimize inventory management include:

Accurate demand forecasting

Traditional inventory management often relies on experience and historical data for forecasting, but this method may lead to inventory backlogs or out-of-stock due to demand fluctuations and market changes. Through big data and intelligent algorithms, roofing material manufacturers can more accurately predict future demand changes. For example, by analyzing climate change, policy changes in the construction industry, and customer orders, accurate forecasts of future market demand can be made. Accurate demand forecasting helps companies maintain the most appropriate inventory level and avoid excessive or insufficient inventory.

Just-In-Time (JIT) Management

Just-In-Time (JIT) is an important concept in lean production. It requires companies to produce the required products exactly when they are needed to avoid excessive inventory backlogs. In the production of roofing materials, JIT management means that raw materials, semi-finished products, and finished products are produced and distributed according to actual demand, rather than purchased and stored in large quantities in advance. By establishing a close cooperative relationship with suppliers, roofing material manufacturers can ensure that raw materials are obtained in a timely manner when needed, avoiding excessive inventory that leads to capital occupation and increased management costs.

Automated Inventory Management System

With the advancement of information technology, many Chinese Roofing Materials Manufacturers have introduced automated inventory management systems that can monitor inventory in real time and automatically adjust procurement and production plans according to actual needs. Using IoT technology, companies can achieve accurate management of inventory, automatically record the inbound and outbound conditions of each batch, and thus reduce errors and delays in manual operations. Automated inventory systems can effectively avoid human errors, reduce the problem of excess or shortage inventory, and improve inventory turnover efficiency.

Supply Chain Visualization

With the improvement of the informationization of supply chain management, more and more roofing material manufacturers are adopting supply chain visualization tools. These tools can help management track the inventory status, production progress, transportation and delivery of raw materials in real time to ensure efficient collaboration of all links in the supply chain. Through the transparency of the supply chain, manufacturers can understand the changes in various indicators in real time, adjust production plans in a timely manner, and avoid production and inventory management problems caused by information asymmetry.

Safety Stock and Buffer Stock

When facing uncertain market demand, roofing material manufacturers usually set up a certain amount of safety stock or buffer stock. This part of the inventory can effectively cope with short-term demand fluctuations or supply chain disruptions. In the face of sudden weather changes or a surge in orders, buffer inventory can ensure that production is not delayed and customer needs are met. By setting up safety stocks reasonably, companies can ensure the continuity of production and the timeliness of supply without affecting the flow of funds.

3. The synergy between lean production and inventory management

The mutual collaboration of lean production and inventory management in the supply chain enables roofing material manufacturers to respond to changes in market demand more flexibly during the production process. Through lean production, companies can maximize the use of existing resources and improve production efficiency; and by optimizing inventory management, companies can reduce capital occupation and inventory costs, and ensure that production lines are not affected by raw material shortages. The effective combination of the two not only improves the smoothness of the production process, but also improves the timeliness of product delivery and customer satisfaction.

Email:

Email: Phone:

Phone: Adress:

Adress: