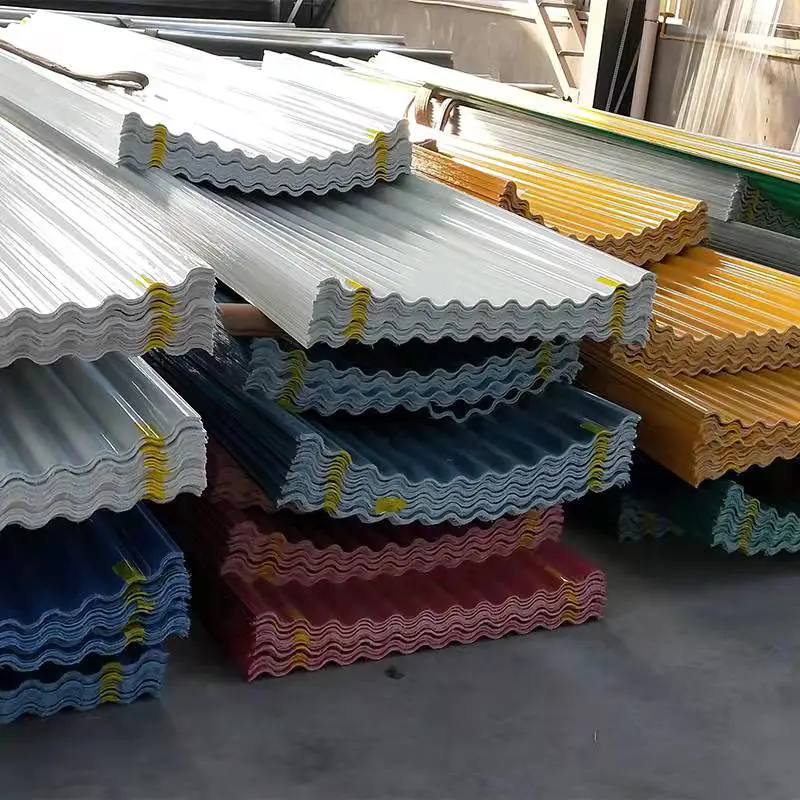

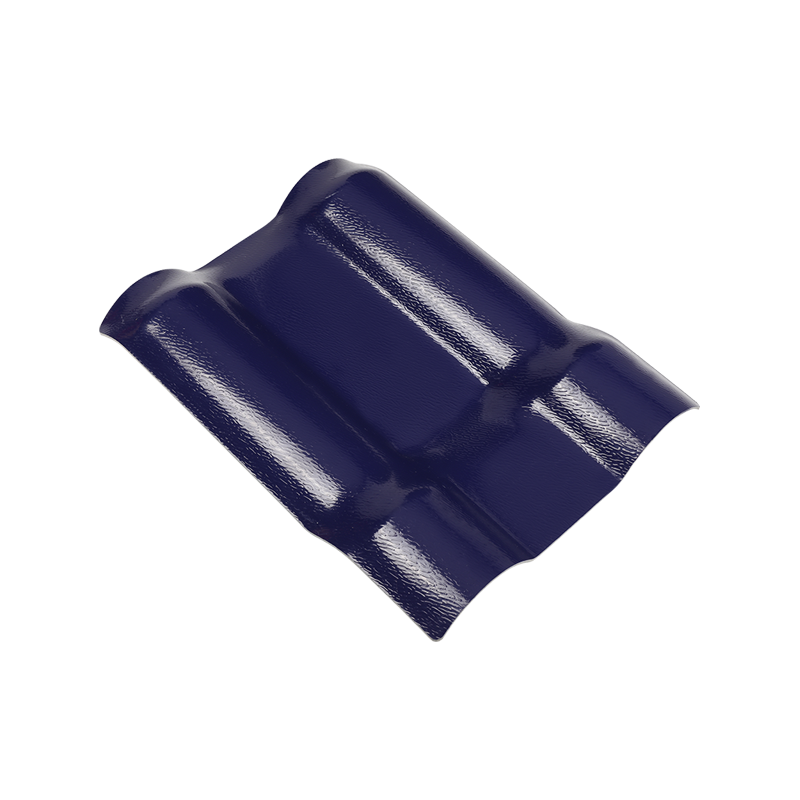

1. Importance of weatherability

Weatherability refers to the ability of a material to maintain performance and appearance under various natural environmental conditions, especially when exposed to environmental factors such as sunlight, wind and rain, cold or high temperature for a long time. The weatherability of FRP daylighting panels is closely related to the resin, reinforcement materials, coatings and processing technology used. Good weatherability not only prolongs the service life of FRP daylighting panels, but also ensures that they maintain stable performance and will not deform, corrode, fade or lose strength due to environmental changes.

Common environmental factors for FRP daylighting panels include:

Ultraviolet rays: Ultraviolet rays are a type of electromagnetic wave in solar radiation. They are extremely destructive to building materials and can accelerate the aging, embrittlement, discoloration and degradation of materials.

Temperature changes: Extreme temperature changes can cause materials to expand or contract, affecting the integrity of the structure.

Humidity and precipitation: Long-term exposure to moisture and precipitation may cause corrosion or moisture penetration of the material, affecting the performance of the panel.

Wind and impact: Climate factors such as strong winds or sandstorms may cause FRP panels to crack, fade or surface damage.

FRP solar panels need to have strong weather resistance and be able to resist the erosion of these natural factors to ensure their long-term stable operation.

2. The criticality of anti-ultraviolet performance

Ultraviolet rays (UV) are one of the most destructive factors in the natural environment. Long-term exposure to UV rays can cause significant changes in the structure of the material. For FRP solar panels, the effects of UV rays are mainly manifested in:

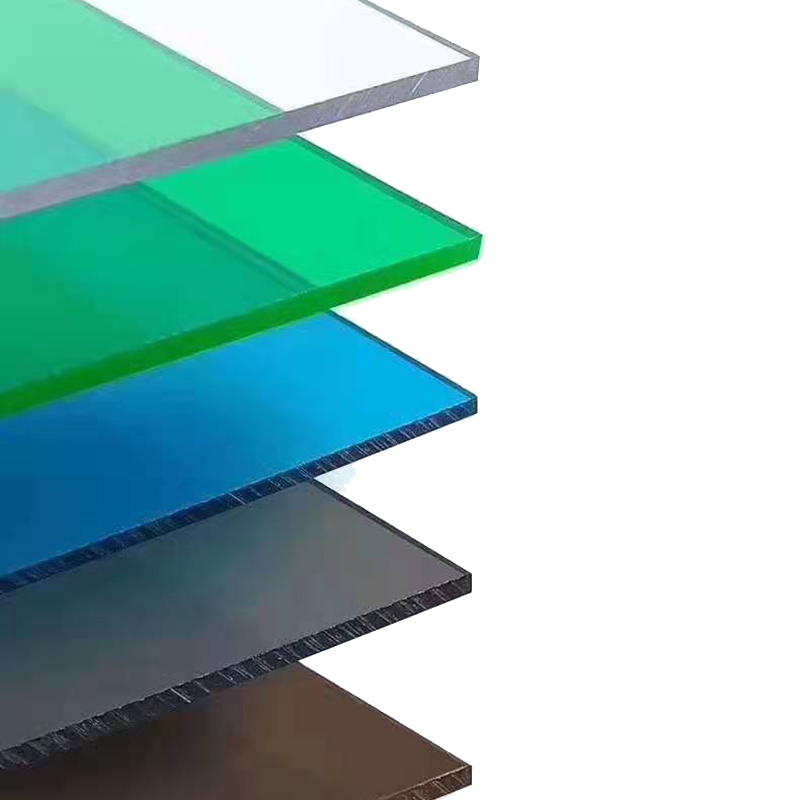

Degradation of resin: The core structure of FRP solar panels is composed of resin and reinforcing materials (such as glass fiber), and resin is one of the main "victims". Long-term UV exposure can cause the resin chain to break, causing it to lose its original physical and chemical properties, making the FRP solar panel brittle, hardened, or even cracked.

Fading and loss of transparency: UV rays can also cause the surface of the resin to discolor, fade, yellow or mottled, affecting the appearance. The impact of UV rays on transparency cannot be ignored. Excessive UV exposure may make the board no longer transparent, affecting the lighting effect.

Reduced strength: UV exposure can also affect the mechanical properties of FRP solar panels, including its compressive strength, tensile strength and bending resistance. Long-term exposure to ultraviolet rays may cause the strength of the panels to gradually decrease, increasing the risk of breakage.

In order to ensure the long-term use of FRP daylighting panels, anti-ultraviolet performance is an indicator that cannot be ignored.

3. UV protection technology of FRP daylighting panels

Modern FRP daylighting panels usually use the following technologies to enhance their anti-ultraviolet ability:

(1) UV protection layer

In order to enhance the anti-ultraviolet performance of FRP daylighting panels, many FRP daylighting panels are coated with a special UV protection coating on the surface. These coatings usually contain anti-ultraviolet additives (such as titanium dioxide, zinc oxide, etc.), which can effectively absorb or reflect ultraviolet rays and prevent ultraviolet rays from directly acting on the resin layer of the panel. The UV protection layer can greatly improve the anti-ultraviolet performance of the panel and extend its service life.

(2) Anti-ultraviolet resin

In addition to the surface coating, high-quality FRP daylighting panels also use anti-ultraviolet resins, which themselves have strong ultraviolet absorption and shielding capabilities. Such resins are often added with anti-ultraviolet additives during the manufacturing process, which can prevent long-term exposure to ultraviolet rays from damaging the resin body, thereby fundamentally improving the weather resistance of the panel.

(3) Composite material reinforcement

In order to further improve the UV resistance of FRP daylight panels, some high-end products will also add reinforcement materials to the resin layer, such as high-performance glass fiber or carbon fiber. These reinforcement materials can not only improve the mechanical strength of the board, but also improve its UV resistance to a certain extent, because these materials usually have strong UV resistance and can reduce the impact of UV on the resin.

4. How to evaluate the weather resistance and UV resistance of FRP daylight panels

When selecting FRP daylight panels, the following points should be noted when evaluating their weather resistance and UV resistance:

Product certification: Choose products with relevant certifications, such as ISO 9001 quality certification, CE certification, etc. High-quality FRP daylight panels will indicate their specific UV resistance performance in the product manual, or prove their weather resistance through third-party testing.

Service life: Many manufacturers will provide an estimate of the service life of FRP daylight panels. Generally, high-quality FRP daylight panels can provide more than 10 years of effective service, while some medium and low-quality products may show obvious degradation after 3-5 years.

Experimental data: By checking the UV resistance test report provided by the supplier, you can understand its UV resistance. Some manufacturers will conduct accelerated UV aging tests to simulate the effects of long-term UV exposure on materials and provide test results to help customers judge the product's UV resistance.

Email:

Email: Phone:

Phone: Adress:

Adress: